Precision Custom Manufacturing Solutions for Your Industry

Unique solutions for each customer we serve.

Take a virtual flyover tour of Plainsman Mfg.

Take a virtual flyover tour of Plainsman Mfg.

Get a bird’s-eye view of our 44,000 sq. ft. manufacturing facility in Edmonton. See where precision engineering, advanced machining, and quality craftsmanship come together to serve the oil & gas, pipeline, and industrial sectors.

Precision Manufacturing. Scalable Solutions

With over 50 years of expertise, we deliver end-to-end manufacturing solutions that integrate seamlessly into supply chains. As an ISO 9001:2015-certified facility, we uphold the highest standards of precision, efficiency, and cost-effectiveness, helping our clients optimize performance and reduce costs.

Our facilities include:

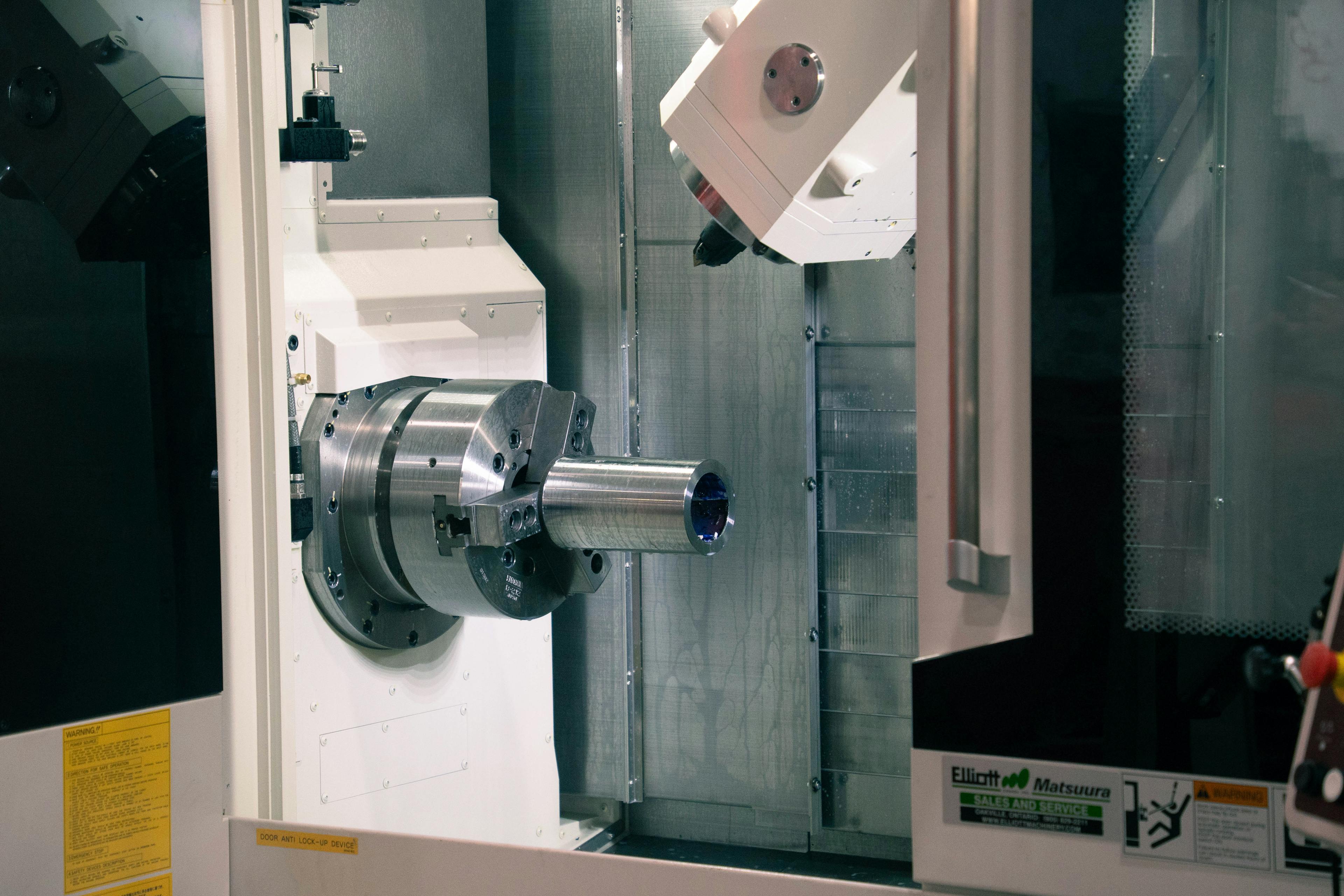

- Main Facility: 44,000 sq. ft. with 5 milling machines and 28 turning centers

- Secondary Facility: 7,000 sq. ft. with 1 milling machine and 9 turning centers

Our Capabilities:

- Custom Machining – CNC turning, milling, and threading for high-precision components

- Fabrication & Welding – Certified welding to ISO and ASTM standards

- Surface Treatments – Phosphate coating for corrosion resistance

- Assembly & Testing – Turnkey multi-component assembly with pressure testing up to 10,000 PSI